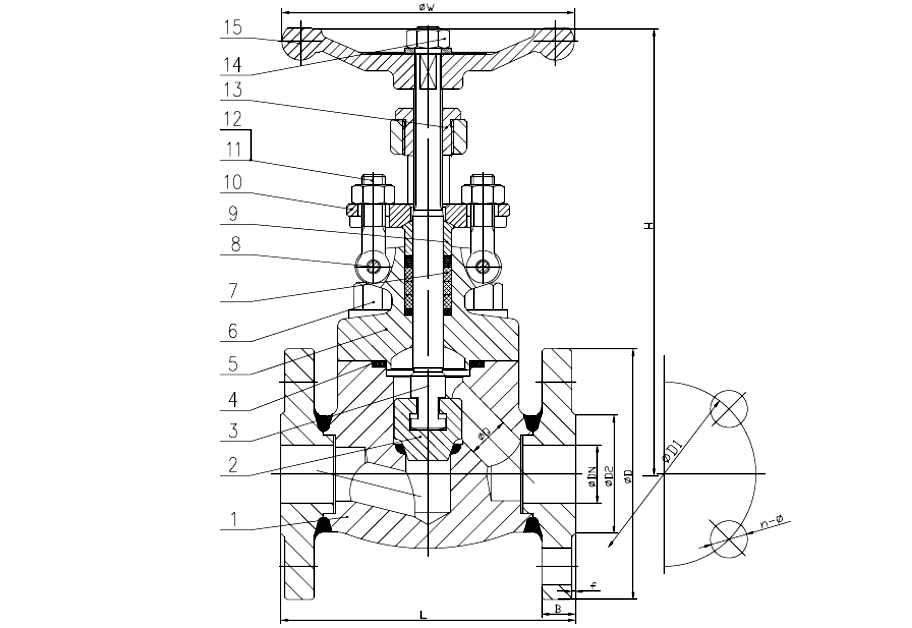

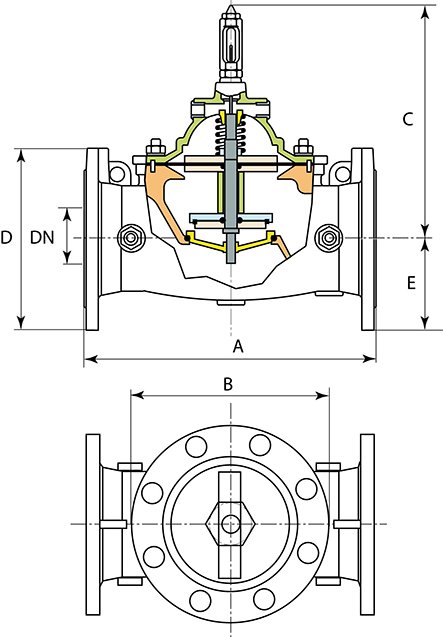

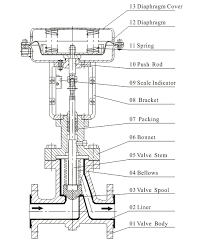

Fusion Bonded Epoxy (FBE) Coated Gate Valves are engineered to provide superior protection against corrosion and wear in demanding industrial environments. The FBE coating is applied through a heat-induced bonding process, creating a seamless, durable layer that offers long-lasting resistance to chemicals, moisture, and mechanical damage. These valves are specifically designed for industries such as water treatment, oil & gas, petrochemical, and wastewater management, where reliable performance and longevity are critical. The FBE coating ensures enhanced protection in harsh conditions, extending the valve’s service life even in corrosive or abrasive applications.

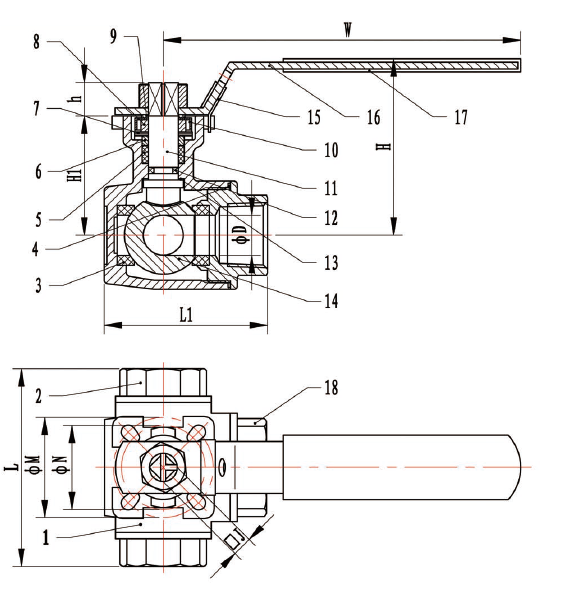

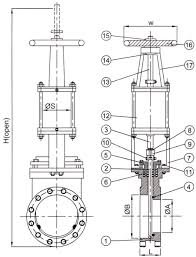

Specifications:

- Nominal Diameter: DN50 to DN1200

- Nominal Pressure: Class 150 to Class 2500

- End Connection:

- Flanged (ASME B16.5)

- Butt Weld (ASME B16.25)

- Socket Weld (ASME B16.11)

Design Standards:

- API 600

- ASME B16.34

- ISO 12944 (Corrosion Protection)

- ISO 9001

Manufacturers:

- KITZ Fusion Bonded Epoxy Coated Gate Valve

- PMC Fusion Bonded Epoxy Coated Gate Valve

- AMPO Fusion Bonded Epoxy Coated Gate Valve

- VELAN Fusion Bonded Epoxy Coated Gate Valve

We also source high-quality FBE Coated Gate Valves from reliable suppliers in China, India, and USA/Europe, offering cost-effective solutions without compromising on quality or performance. Our extensive global supply network ensures that we meet your specific project requirements with precision and reliability.

Applications:

Fusion Bonded Epoxy Coated Gate Valves are widely used in industries that require robust corrosion resistance and long service life in harsh environments, including:

- Water Treatment Plants

- Oil & Gas Pipelines

- Petrochemical Industries

- Wastewater Management

- Power Generation

- Desalination Plants

The FBE coating provides superior protection against rust, oxidation, and chemical exposure, making these valves ideal for handling water, chemicals, and other fluids in high-pressure systems. The durable coating extends the life of the valve by preventing corrosion, even in highly corrosive environments.

Our Fusion Bonded Epoxy Coated Gate Valves ensure leak-proof performance, corrosion resistance, and extended service life, making them a trusted solution in demanding industrial applications. With flexible material customizations and sourcing options, we offer tailored solutions for your specific operational needs.

For more information about our products and services, or to discuss your specific valve requirements, feel free to contact us.