Threaded Flange is a versatile connection solution designed for easy installation and removal without the need for welding. This flange type is ideal for use in low-pressure piping systems, hazardous areas where welding is not feasible, and applications requiring quick assembly or disassembly. It is widely used in oil and gas, petrochemical, water treatment, plumbing, and industrial processing applications. The threaded connection allows for a secure, leak-resistant fit with pipes that have external threads, making it suitable for systems operating under moderate pressures.

Constructed from durable materials like carbon steel, stainless steel, and alloy steel, the Threaded Flange offers excellent resistance to corrosion, mechanical stress, and temperature fluctuations. It adheres to stringent industry standards to ensure reliable and safe performance.

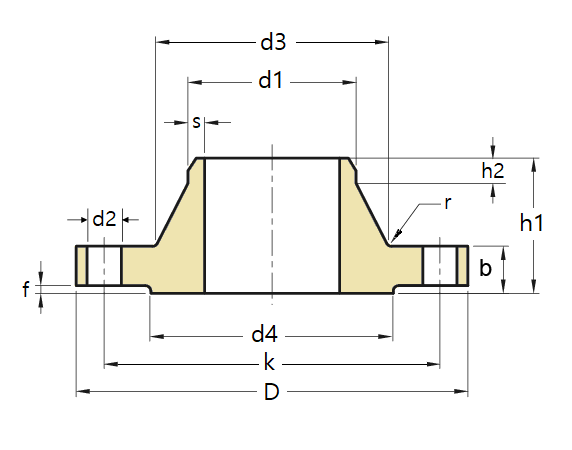

Specifications:

- Size Range: 1/2 inch to 24 inches

- Pressure Class: Class 150 to Class 2500

- Connection Type: Threaded

- Material Options: Carbon Steel (ASTM A105), Stainless Steel (ASTM A182 F304/F316), Alloy Steel

- Design Standards:

- ASME B16.5

- ASTM A182

- ISO 7005

Manufacturers:

- Bonney Forge

- Cooper Industries

- JF Engineering

- SVR

Applications:

- Oil & Gas Pipelines

- Chemical and Petrochemical Plants

- Water and Wastewater Systems

- Plumbing and HVAC Systems

- Industrial Piping Systems

Advantages:

- Easy Installation: No welding required, making it simple to install and remove.

- Leak-Resistant Fit: Provides a secure and tight threaded connection.

- Versatile Material Options: Suitable for a wide range of applications and environments.

- Durable Construction: Resists corrosion, temperature changes, and mechanical stress

For more information or to discuss your specific requirements, contact us today. Our Threaded Flanges provide reliable, efficient, and high-performance solutions for industrial and commercial systems.