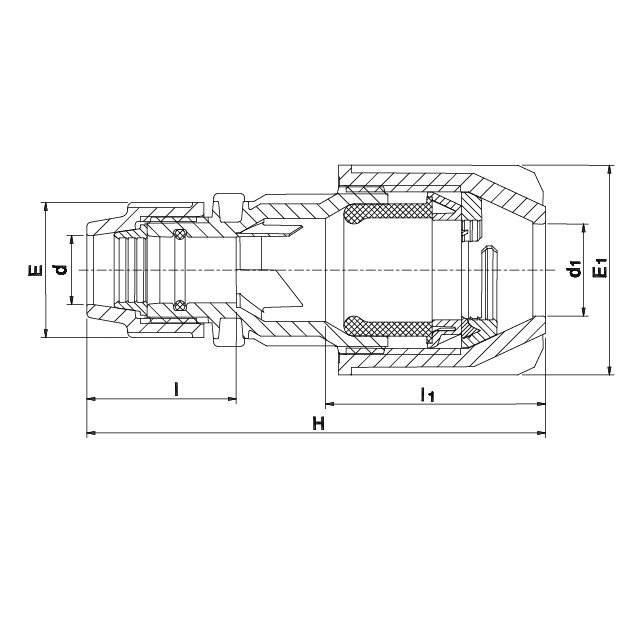

Spacer Coupling is designed to connect two shafts in a mechanical system while providing a fixed distance between them, offering flexibility, alignment, and easy maintenance access. It is commonly used in pumps, compressors, motors, turbines, and other rotating machinery across industries such as oil and gas, petrochemical, power generation, water treatment, and industrial processing. By incorporating a spacer between the coupling halves, this design facilitates easy removal and servicing of connected equipment without having to disassemble the entire system.

Spacer Couplings are engineered to handle high torque, misalignment, and vibration, enhancing operational efficiency and extending the lifespan of machinery. Constructed from durable materials like carbon steel, stainless steel, and alloy steel, they meet stringent industry standards for performance, reliability, and safety.

Specifications:

- Size Range: Custom sizes available based on system requirements

- Torque Capacity: Up to high-torque industrial specifications

- Material Options: Carbon Steel, Stainless Steel, Alloy Steel

- Design Standards:

- AGMA, API, or customer-specific standards

Manufacturers:

- Rexnord

- Lovejoy

- SVR

- Martin Sprocket & Gear

Applications:

- Pumps and Compressors

- Industrial Rotating Machinery

- Motors and Turbines

- Power Generation Systems

- Oil & Gas Pipelines

Advantages:

- Flexible Alignment: Compensates for misalignment and vibration.

- Easy Maintenance: Spacer allows for easy removal and servicing without full disassembly.

- High Torque Capacity: Suitable for heavy-duty industrial applications.

- Durable Construction: Designed to withstand harsh operational conditions.

For more information or to discuss your specific needs, contact us today. Our Spacer Couplings provide reliable, efficient, and high-performance solutions for industrial and commercial systems.