Eccentric Reducer is a type of pipe fitting used to connect pipes of different diameters while maintaining a smooth flow transition, reducing the risk of turbulence and minimizing pressure loss. Unlike concentric reducers, the eccentric design has an offset centerline, which prevents air accumulation and allows for more effective drainage, making it ideal for horizontal flow systems in oil and gas, petrochemical, water treatment, HVAC systems, and industrial applications.

Constructed from high-quality materials such as carbon steel, stainless steel, alloy steel, and ductile iron, eccentric reducers offer excellent strength, durability, and resistance to corrosion and high-pressure environments. They are manufactured to meet stringent industry standards for reliability and performance.

Specifications:

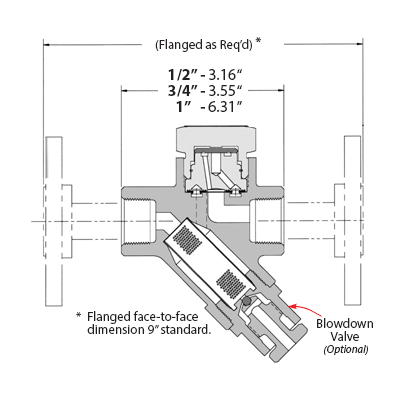

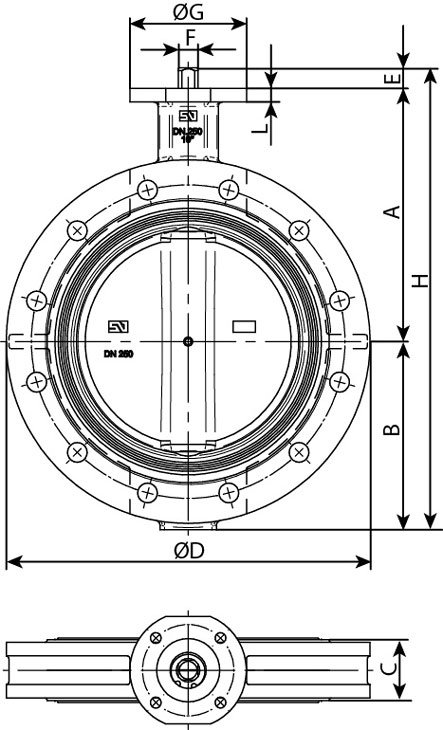

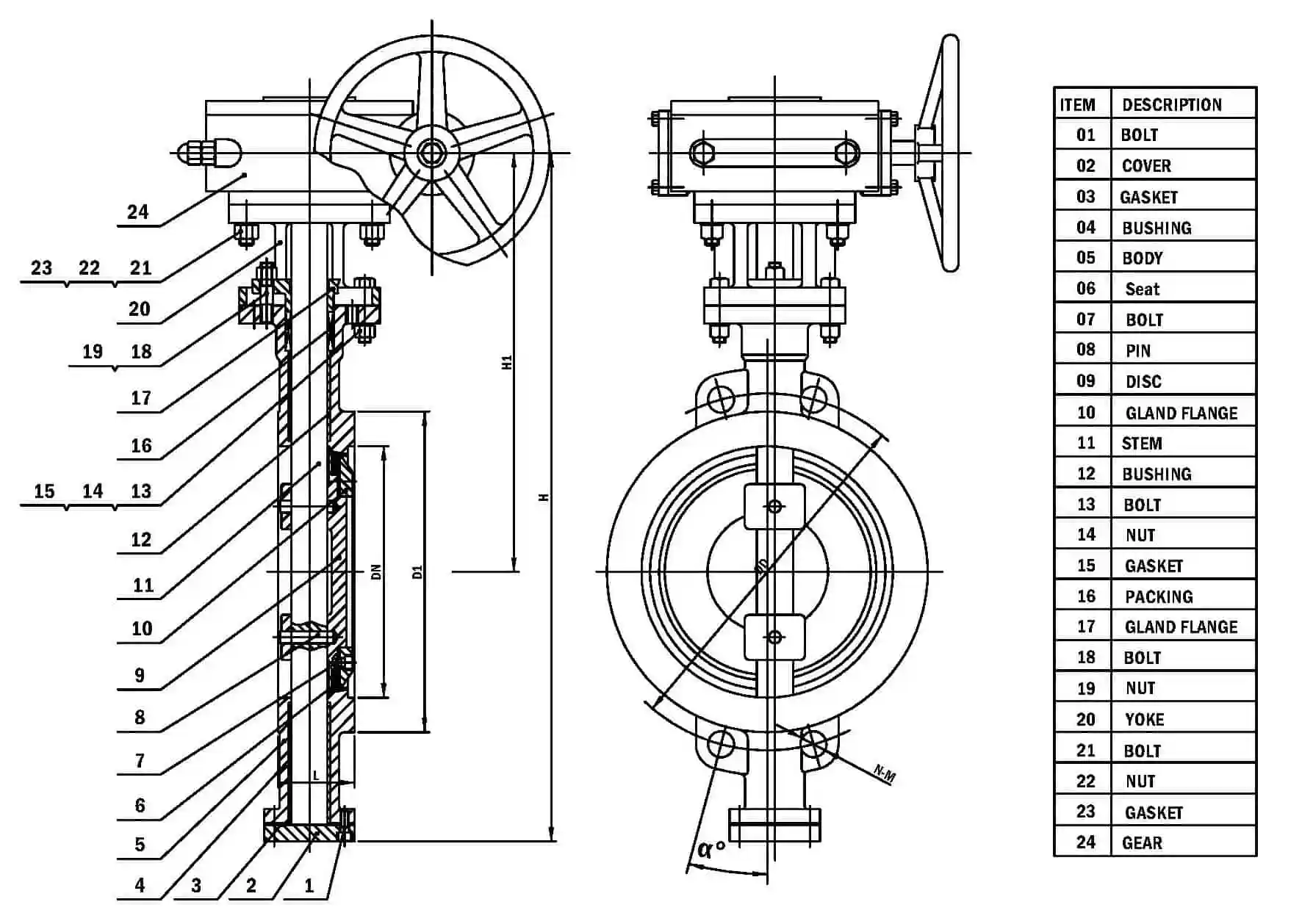

- Size Range: 1/2 inch to 48 inches

- Pressure Rating: PN10 to PN40 and beyond

- Material Options: Carbon Steel (ASTM A234 WPB), Stainless Steel (ASTM A403 WP304/316), Alloy Steel, Ductile Iron

- Design Standards:

- ASME B16.9

- ISO 9001

- DIN Standards

Manufacturers:

- Bonney Forge

- Allied Group

- JF Engineering

- SVR Eccentric Reducer

Applications:

- Oil & Gas Pipelines

- Petrochemical and Chemical Processing

- Water and Wastewater Systems

- HVAC Systems

- Industrial Fluid Handling Systems

Advantages:

- Offset Design: Prevents air accumulation in pipelines, making it ideal for horizontal flow.

- Reduced Pressure Loss: Ensures smooth flow transitions with minimal turbulence.

- High Strength and Durability: Suitable for high-pressure and high-temperature conditions.

- Wide Range of Sizes: Customizable to suit different operational requirements.

For more information or to discuss your project needs, contact us today. Our Eccentric Reducers provide reliable, high-performance solutions for a variety of piping systems.