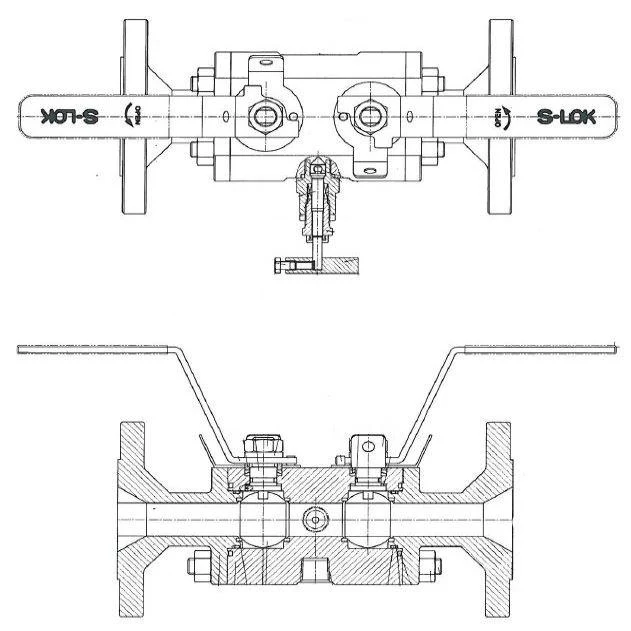

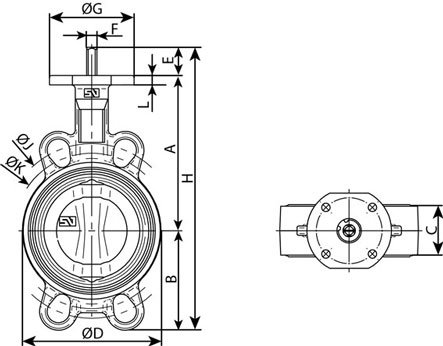

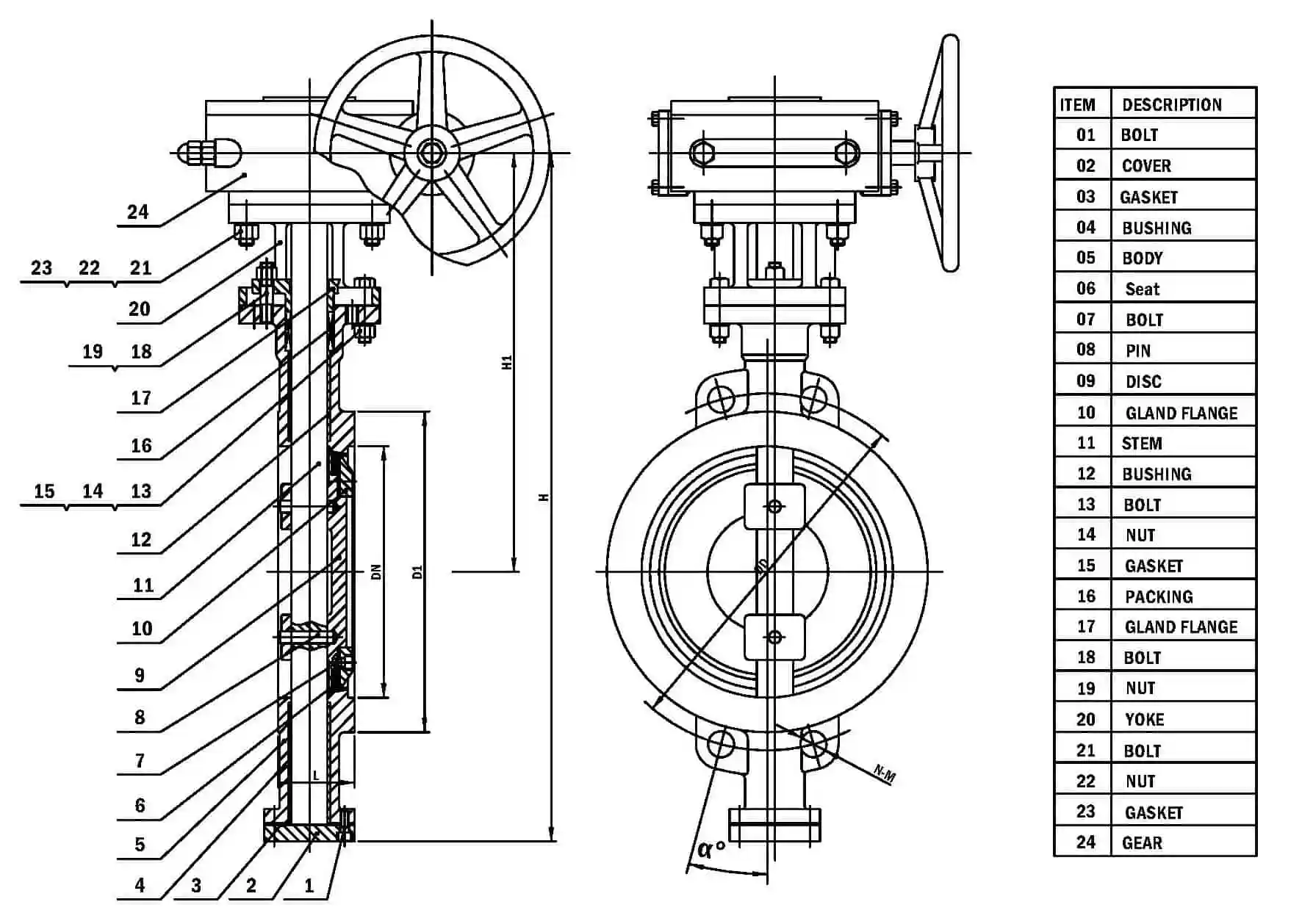

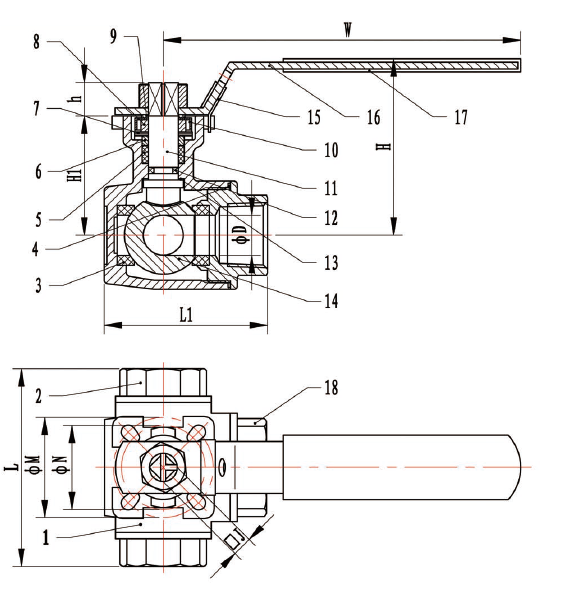

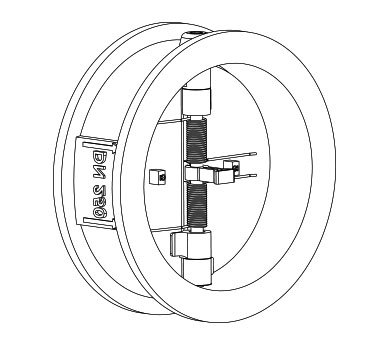

Double Block and Bleed Valve (DBB) is a specialized valve assembly designed to provide a secure, leak-proof seal, ensuring isolation and safety in critical applications. This valve combines two block valves and a bleed valve into a single unit, offering reliable isolation by blocking flow from both directions and bleeding off any trapped pressure between the block valves. DBB valves are essential for applications requiring absolute safety and leak prevention, making them ideal for industries such as oil & gas, chemical processing, petrochemical, and power generation.

Constructed from high-grade materials such as stainless steel, carbon steel, or alloy, Double Block and Bleed Valves are engineered to withstand high pressures and temperatures. They meet stringent industry standards, ensuring consistent performance and safety in high-risk environments.

Specifications:

- Size Range: ½ inch to 12 inches

- Pressure Rating: Class 150 to Class 2500

- End Connection:

- Flanged (ASME B16.5)

- Threaded (ASME B1.20.1)

- Butt Weld (ASME B16.25)

- Design Standards:

- API 6D

- ASME B16.34

- ISO 9001

Manufacturers:

- Cameron Double Block and Bleed Valve

- Parker Double Block and Bleed Valve

- SVR DBB

- Swagelok Double Block and Bleed Valve

We source high-quality Double Block and Bleed Valves from trusted manufacturers worldwide, ensuring superior performance, safety, and durability.

Applications:

Double Block and Bleed Valves are commonly used in applications requiring positive isolation and leak detection, such as:

- Oil & Gas Transmission Lines

- Chemical and Petrochemical Processing

- Power Generation

- Refinery Operations

- Instrumentation Isolation

These valves are particularly useful for applications requiring high safety standards, where preventing cross-contamination and maintaining isolation is critical.

For more information on our Double Block and Bleed Valves or to discuss your specific isolation requirements, contact us today. Our DBB valves deliver dependable isolation, safety, and performance for high-risk industrial environments.