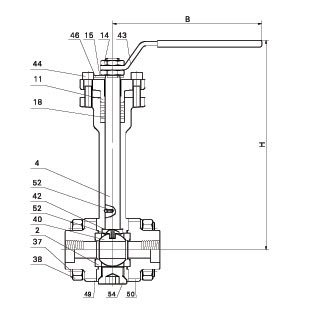

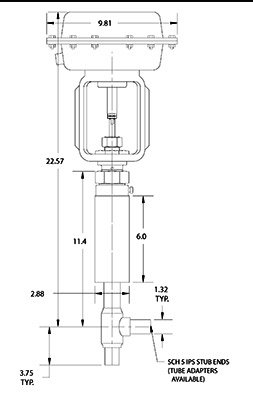

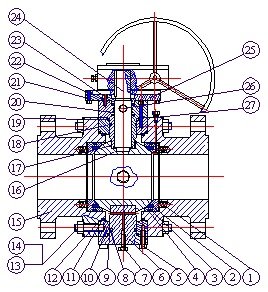

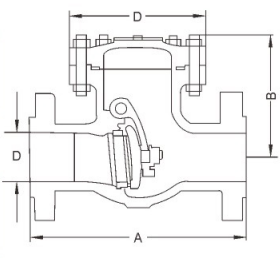

Cryogenic Ball Valves are specifically designed to handle extremely low temperatures, making them ideal for controlling the flow of cryogenic fluids such as liquefied natural gas (LNG), liquefied petroleum gas (LPG), and other cryogenic gases. These valves are constructed with special materials and features to ensure reliable performance in extreme conditions where standard valves may fail. The design includes an extended bonnet to insulate the stem from the cryogenic fluid, preventing freezing and ensuring smooth operation.

Manufacturers

We source high-quality Cryogenic Ball Valves from leading global manufacturers, ensuring top performance and durability in extreme conditions. Manufacturers include:

Applications

Cryogenic Ball Valves are critical for industries that deal with low-temperature gases and fluids. Their reliable operation and robust construction make them essential in the following applications:

- Liquefied Natural Gas (LNG) Processing and Storage

- Liquefied Petroleum Gas (LPG) Systems

- Cryogenic Gas Storage Facilities

- Air Separation Units

- Petrochemical and Chemical Processing

- Marine Applications (for transporting cryogenic fluids)

- Refining Plants

- Cryogenic Pipeline Systems

Key Features and Benefits

- Extended Bonnet: The extended bonnet insulates the valve’s stem from the cryogenic fluid, preventing freezing and ensuring smooth, efficient operation.

- Leak-Proof Sealing: The specialized seat and packing materials ensure reliable sealing, preventing leaks even at extreme temperatures.

- Durability in Harsh Conditions: Built from corrosion-resistant materials such as stainless steel and low-temperature carbon steel, these valves can withstand both cryogenic and high-pressure environments.

- Versatility: Suitable for a wide range of cryogenic fluids, including LNG, LPG, and industrial gases like oxygen and nitrogen.

- Efficient Flow Control: The ball valve design allows for quick and precise control of flow, making these valves ideal for both on/off and throttling applications.

Our Cryogenic Ball Valves provide reliable, leak-proof performance in extreme conditions. With customizable materials, flexible designs, and global certifications, we offer tailored solutions for your cryogenic system needs.

For more information about our products and services, or to discuss your specific valve requirements, please feel free to contact us.