Flap Check Valve is a non-return valve designed to prevent backflow in water and utility pipelines. It operates automatically using a rubber-lined flap, which opens with forward flow and closes immediately when flow reverses.

Flap Check Valves are preferred in low-pressure and gravity flow systems due to their low head loss, simple design, and maintenance-free operation.

Key Functions

-

Prevents reverse flow and protects pipelines

-

Provides tight shut-off with rubber-lined flap

-

Low pressure drop compared to swing check valves

-

Suitable for horizontal or vertical installation

-

Silent operation with minimal water hammer

Design & Testing Standards

-

EN 1074-3

-

ASME B16.34

-

API 598 – Pressure & seat leakage testing

-

ISO 9001 – Quality Management

Applications

Flap Check Valves are widely used in:

-

Water distribution networks

-

Sewage & wastewater pipelines

-

Drainage and stormwater systems

-

Pump discharge lines

-

Desalination and water treatment plants

-

District cooling and utility pipelines

GCC Valves – Product Assurance

GCC Valves supplies high-quality Flap Check Valves meeting the QA/QC requirements of major GCC utilities and EPC contractors.

We provide:

-

EN 10204 3.1 Material Test Certificates

-

Hydrostatic & functional test reports

-

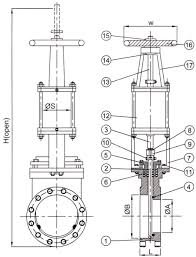

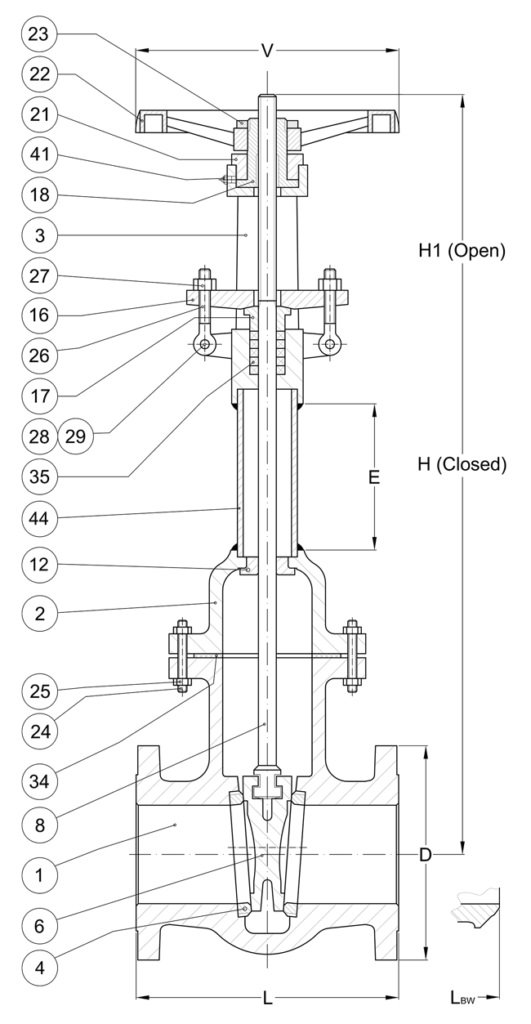

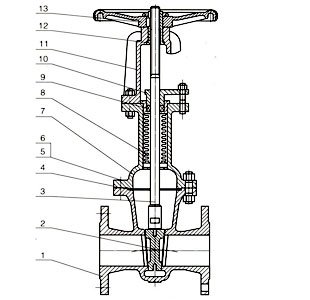

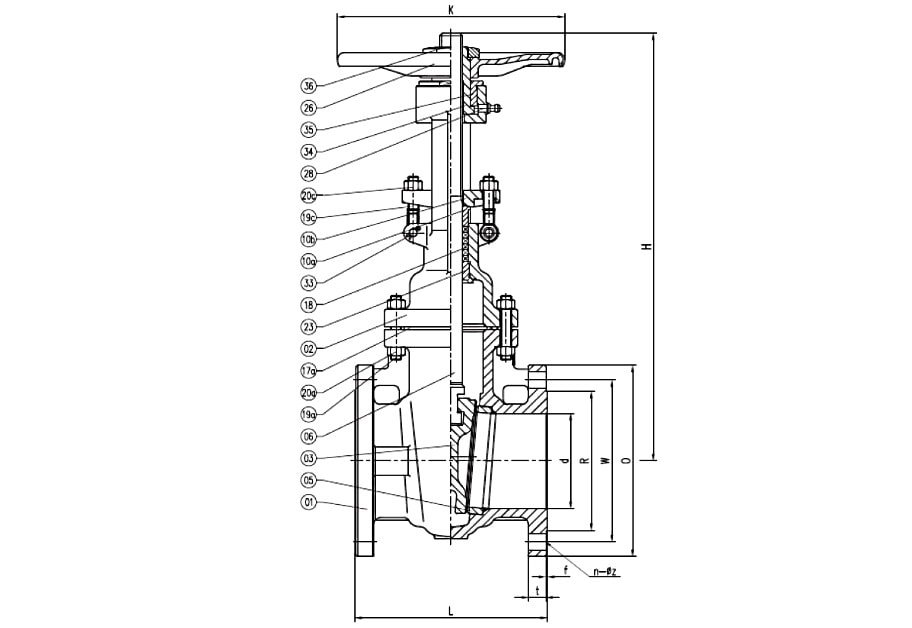

Datasheets and GA drawings

-

Complete QA/QC documentation packages

(ITP, coating certificates, inspection reports)

Our Flap Check Valves are sourced from certified manufacturers in Europe, India, and China, compliant with project specifications used by SWCC, NWC, ARAMCO, ADNOC, SABIC, MARAFIQ, and BAPCO. For fittings check our MiddleEastPiping.com