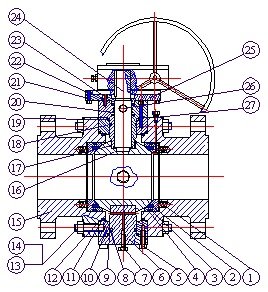

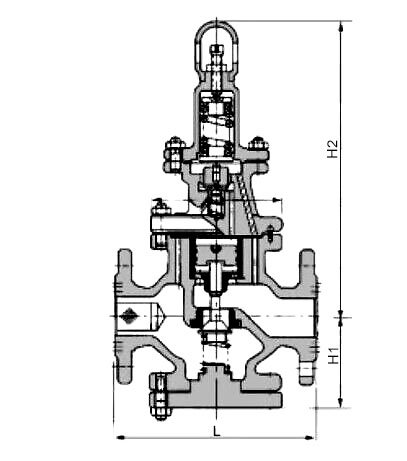

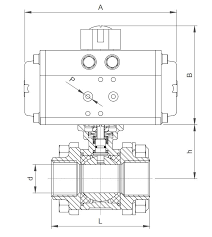

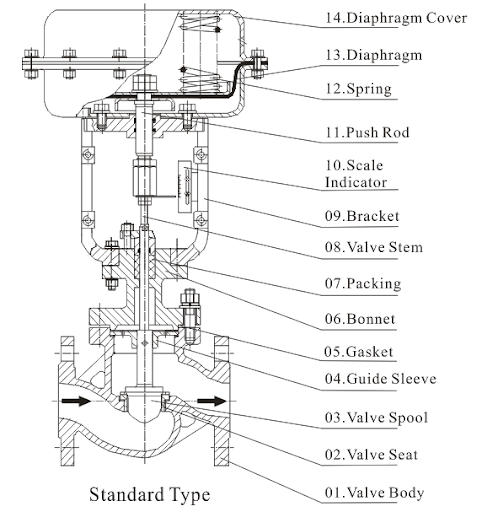

Trunnion Ball Valve is designed for high-pressure and large-diameter applications, offering robust and reliable performance in various industries. Unlike floating ball valves, trunnion-mounted ball valves feature additional anchoring at the top and bottom of the ball, reducing the load on the valve seats and ensuring lower operating torque. This design makes trunnion ball valves ideal for handling high-pressure fluids, gases, and slurries, providing tight shut-off and long service life.

These valves are widely used in industries such as oil & gas, petrochemical, power generation, and water treatment, where reliability and durability are essential. Trunnion ball valves are available in a variety of materials and configurations to meet specific industrial requirements, and they are suitable for both on/off and throttling applications.

Key Features:

- Trunnion-Mounted Design: Provides additional support to the ball, reducing seat wear and lowering the required operating torque.

- Tight Shut-Off: Ensures a leak-proof seal even under high-pressure conditions, making it suitable for critical applications.

- High-Pressure Capability: Ideal for handling high-pressure fluids and gases in both upstream and downstream applications.

- Double Block and Bleed (DBB) Capability: Ensures complete isolation and safety during maintenance operations.

- Durable Construction: Built from high-quality materials to withstand corrosive environments, high pressures, and extreme temperatures.

Manufacturers:

- KITZ

- VELAN

- SVR

- FLOWORK

- CAMERON

Applications:

- Oil & Gas Pipelines

- Petrochemical Plants

- Power Generation

- Water Treatment Plants

- Chemical Processing

- Offshore Platforms

- LNG Terminals

- Refining Plants

Benefits:

- Lower Operating Torque: The trunnion-mounted ball reduces the load on the seats, requiring less torque to operate, which allows for smaller actuators and reduced operating costs.

- Extended Seat Life: The trunnion support reduces seat wear, ensuring a longer service life and minimizing maintenance requirements.

- Versatile Applications: Suitable for both on/off and throttling operations, and capable of handling a variety of fluids, gases, and slurries.

- Safety Features: Double block and bleed capability and emergency sealant injection ensure complete isolation and enhance operational safety.

Our Trunnion Ball Valves are engineered to provide reliable and leak-proof performance in high-pressure and large-diameter systems. With customizable materials and flexible designs, these valves are built to meet the specific needs of your critical applications.

For more information about our products and services, or to discuss your specific valve requirements, feel free to contact us.