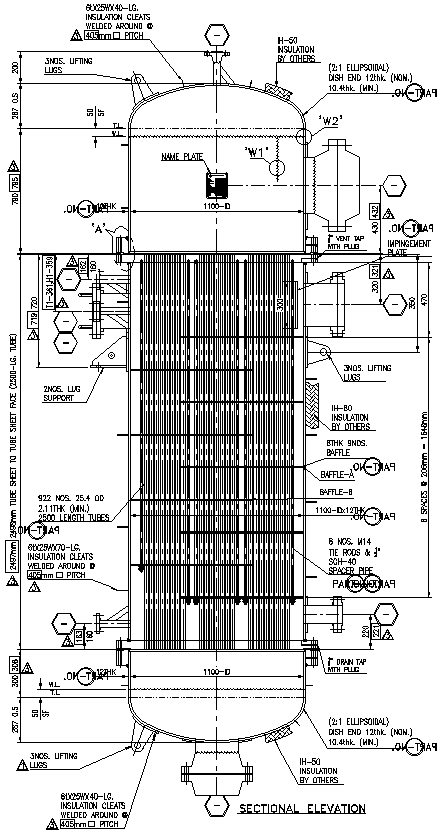

Shell and Tube Heat Exchanger is a robust and efficient device used for transferring heat between two fluids in a wide range of industrial processes. It consists of a series of tubes (tube bundle) enclosed within a cylindrical shell, where one fluid flows through the tubes, while the other fluid flows around the tubes within the shell. This design allows for efficient heat transfer between the fluids, making it ideal for oil and gas processing, chemical and petrochemical plants, power generation, HVAC systems, and other industrial applications.

The shell and tube configuration offers flexibility, durability, and ease of maintenance, and is capable of handling high pressures and temperatures, making it suitable for critical applications.

Specifications:

- Size Range: Custom sizes to meet specific heat transfer requirements

- Material Options: Carbon Steel, Stainless Steel, Alloy Steel, Titanium

- Design Pressure: Up to 3,000 psi (or as per requirement)

- Temperature Range: Suitable for high-temperature applications

- Tube Arrangements: Fixed tube sheet, U-tube, floating head

- Heat Transfer Area: Customizable for specific process needs

- Design Standards:

- ASME Boiler and Pressure Vessel Code

- TEMA (Tubular Exchanger Manufacturers Association) standards

- API 660

Manufacturers:

- Alfa Laval

- SVR

- Heat Exchanger Design, Inc.

- Tranter

Applications:

- Oil & Gas Processing: Heat exchangers are used for preheating crude oil, condensing process streams, and cooling systems.

- Chemical and Petrochemical Plants: Facilitate heat transfer between reactants, products, and process streams.

- Power Generation: Used for steam condensation, cooling, and boiler feedwater heating.

- HVAC Systems: Ensure efficient heating and cooling in large systems.

- Food & Beverage Processing: Used for pasteurization, heating, or cooling of liquids.

Advantages:

- High Heat Transfer Efficiency: Optimized design for maximum heat exchange between fluids.

- Durability: Suitable for high-pressure, high-temperature applications, and corrosive environments.

- Flexibility: Customizable designs for a wide range of heat transfer applications.

- Easy Maintenance: Tube bundles can often be removed for cleaning or maintenance.

For more information or to discuss your project requirements, contact us today. Our Shell and Tube Heat Exchangers deliver high-performance, reliable solutions for a wide range of industrial heat transfer applications.