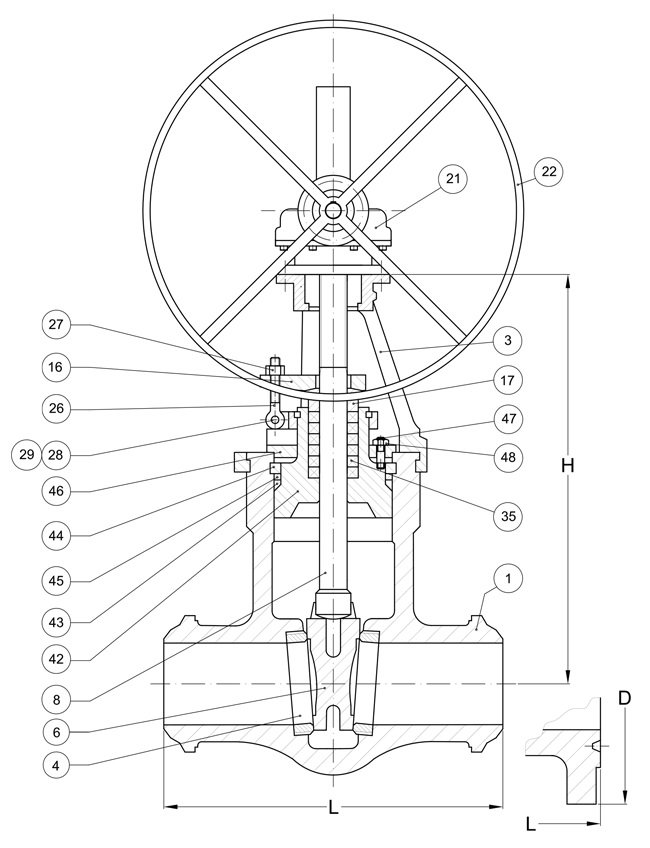

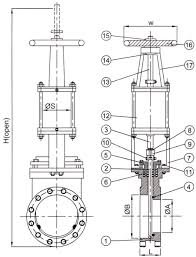

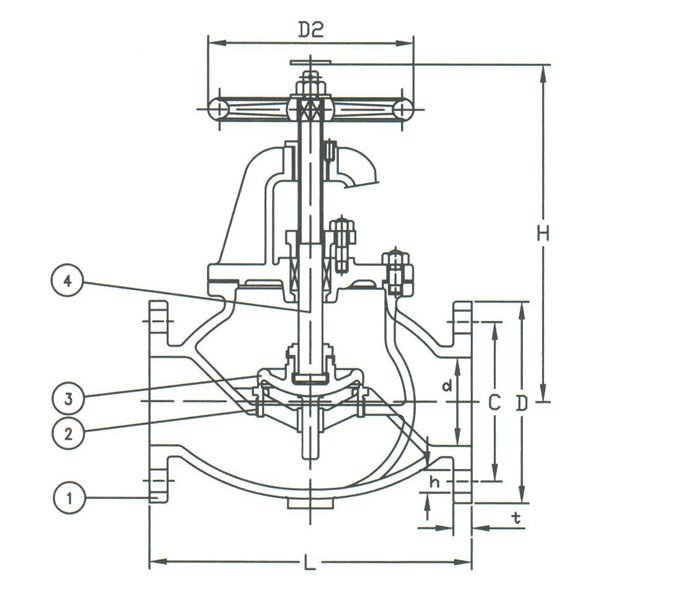

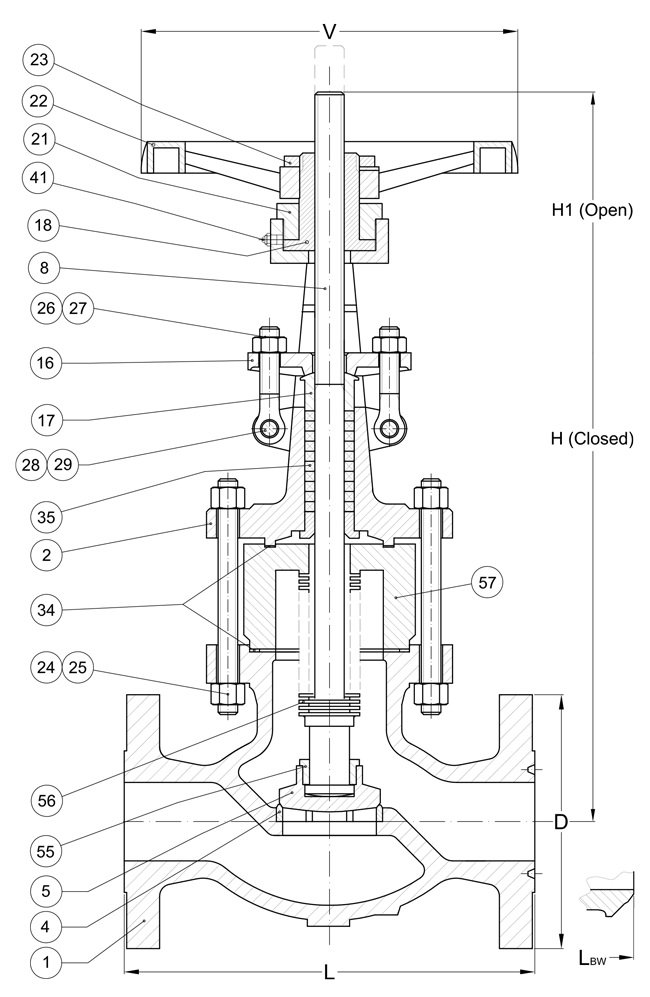

Pressure Seal Globe Valves are specifically designed for high-pressure and high-temperature applications, where durability and leak-tight performance are essential. These valves feature a pressure seal bonnet, which enhances sealing capabilities as internal pressure increases, making them ideal for critical applications such as steam, oil & gas, power generation, and petrochemical industries. The pressure seal design minimizes the risk of leakage, ensuring long-term reliability and safety in demanding environments. Constructed from high-quality materials, Pressure Seal Globe Valves offer exceptional strength, corrosion resistance, and a long service life, even under extreme conditions.

Specifications:

- Nominal Diameter: DN50 to DN600

- Nominal Pressure: Class 600 to Class 2500

- End Connection:

- Flanged (ASME B16.5)

- Butt Weld (ASME B16.25)

Design Standards:

- API 602

- ASME B16.34

- BS 1873

- ISO 9001

Manufacturers:

- KITZ Pressure Seal Globe Valve

- SVR Pressure Seal Globe Valve

- VELAN Pressure Seal Globe Valve

- WEIZIDOM Pressure Seal Globe Valve

We also source high-quality Pressure Seal Globe Valves from trusted suppliers across China, India, and USA/Europe, offering cost-effective solutions without compromising on quality or performance. With our extensive global experience in valve supply, we are well-positioned to meet your specific project requirements.

Applications:

Pressure Seal Globe Valves are widely used in industries requiring high-performance isolation and regulation under extreme pressure and temperature conditions, including:

- Power Generation

- Oil & Gas

- Petrochemical Industries

- Steam Applications

- Refining Plants

- Industrial Processing

These valves are designed for high-pressure systems where dependable flow control and sealing are critical. The pressure seal design reduces the risk of leakage and wear, making them ideal for long-term, reliable service in challenging environments.

Our Pressure Seal Globe Valves provide exceptional performance in high-pressure, high-temperature environments, ensuring optimal flow control and sealing. With various material customizations and sourcing options available, we offer flexible solutions tailored to your specific needs.

For more information about our products and services, or to discuss your specific valve requirements, feel free to contact us.