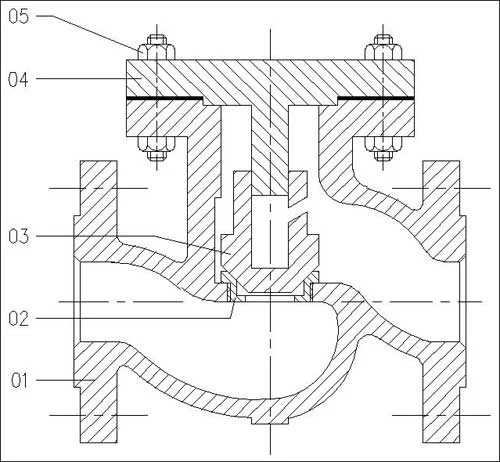

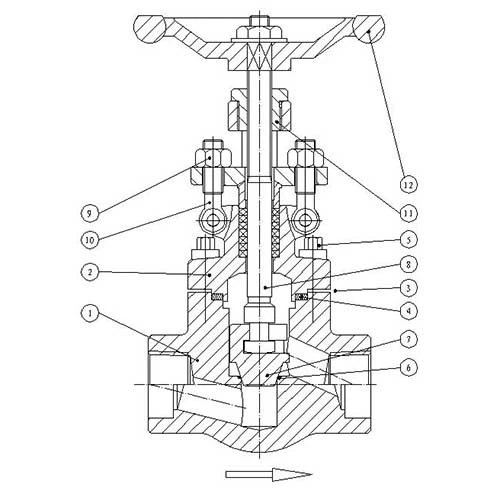

Lift Check Valve are designed to prevent reverse flow in piping systems by allowing fluid to flow in one direction and automatically closing when the flow reverses. The valve operates by lifting a disc off its seat during forward flow and reseating it when the flow stops, preventing backflow. These valves are known for their efficient performance, making them ideal for systems that handle clean, non-turbulent media like water, gas, and oil. Lift Check Valves are commonly used in industries such as oil & gas, petrochemical, and power generation, where maintaining unidirectional flow is critical to system integrity and efficiency.

Specifications:

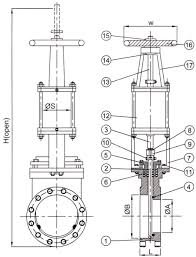

- Nominal Diameter: DN50 to DN1200

- Nominal Pressure: Class 150 to Class 2500

- End Connection:

- Flanged (ASME B16.5)

- Butt Weld (ASME B16.25)

- Socket Weld (ASME B16.11)

Design Standards:

- API 6D

- ASME B16.34

- ISO 9001

Manufacturers:

We also source high-quality Lift Check Valves from trusted suppliers in China, India, and USA/Europe, offering cost-effective solutions without sacrificing performance or durability.

Applications:

Lift Check Valves are widely used in industries requiring reliable backflow prevention, including:

- Oil & Gas

- Chemical Processing

- Petrochemical Industries

- Power Generation

- Water Treatment Plants

- Refining Plants

- Steam and Condensate Systems

These valves are engineered to provide backflow prevention in clean systems with relatively steady flow conditions. They are well-suited for both horizontal and vertical installations in piping systems that demand efficient and automatic operation.

Key Benefits:

- Reliable Backflow Prevention: The lift design ensures efficient flow control and automatic closure when reverse flow occurs.

- Durable and Robust: Built to handle high-pressure and high-temperature environments, ensuring long service life.

- Versatile Applications: Suitable for clean media like water, oil, and gas in various industrial settings.

Our Lift Check Valves provide dependable backflow prevention and system integrity in a wide range of industrial applications. With customizable materials and flexible sourcing options, we offer tailored solutions to meet your specific operational requirements.

For more information about our products and services, or to discuss your specific valve requirements, feel free to contact us.