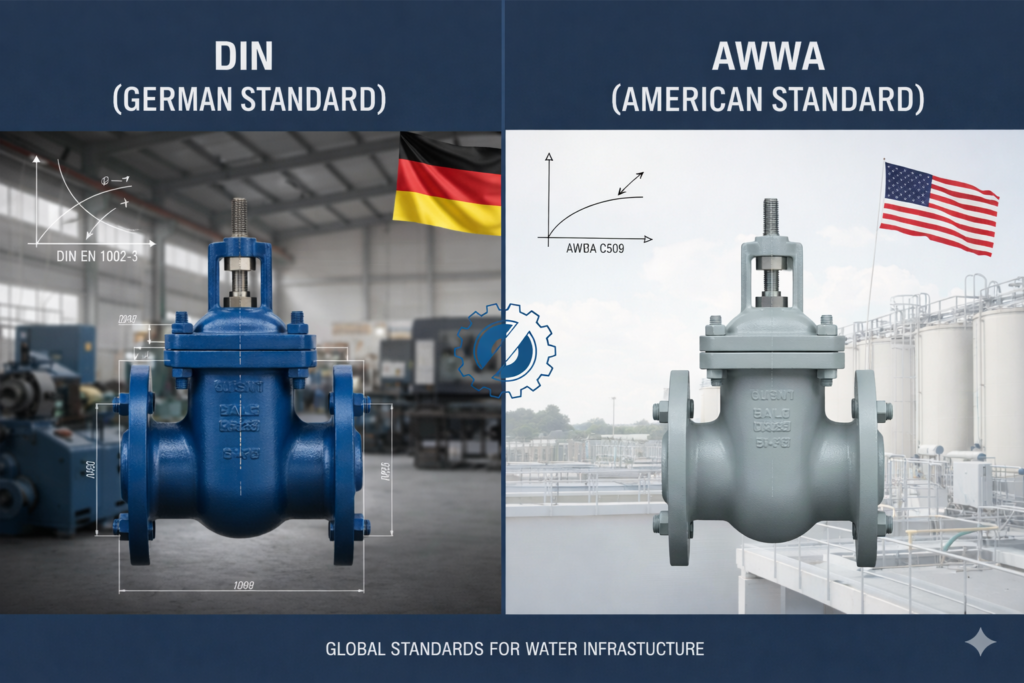

DIN vs AWWA Standards – Key Differences in Valves & Piping Systems

When selecting valves for water, wastewater, district cooling, and utility networks, one of the most common technical questions faced by engineers and procurement teams is whether to specify DIN or AWWA standards.

Both standards are globally recognized, but they differ significantly in design philosophy, pressure ratings, dimensions, testing requirements, and regional adoption. Understanding these differences is essential to avoid compatibility issues, cost overruns, and approval delays.

This blog provides a clear, practical comparison of DIN vs AWWA standards, specifically for valves and water infrastructure projects.

What is DIN?

DIN (Deutsches Institut für Normung) is the German standards organization responsible for developing technical standards widely used across Europe, the Middle East, and Asia.

DIN standards are commonly referenced in:

- Municipal water networks

- District cooling systems

- Desalination plants

- Infrastructure and utility projects

DIN standards are closely aligned with EN (European Norms) and emphasize metric dimensions, PN pressure ratings, and compact valve designs.

What is AWWA?

AWWA (American Water Works Association) develops standards specifically focused on water transmission, distribution, and treatment systems, primarily in North America but also adopted globally for large-diameter water projects.

AWWA standards are widely used in:

- Large municipal pipelines

- Water treatment plants

- Pumping stations

- Fire water networks

AWWA valves are designed with higher safety margins, larger wall thicknesses, and robust construction suitable for long service life in buried and high-flow applications.

DIN vs AWWA – Core Differences

1. Pressure Rating System

| Aspect | DIN | AWWA |

|---|---|---|

| Pressure Rating | PN10, PN16, PN25 | Class 150, 250 |

| Units | Bar | PSI |

| Approach | System-based | Conservative, application-based |

DIN pressure ratings are metric and standardized, while AWWA ratings are application-specific, often designed with higher safety factors for water services.

2. Dimensional Standards

- DIN valves follow EN flange dimensions (EN 1092-2)

- AWWA valves follow ANSI/AWWA flange dimensions

DIN and AWWA flanges are NOT interchangeable, even if pressure ratings appear similar.

3. Size Range

| Standard | Typical Sizes |

|---|---|

| DIN | DN40 to DN1200 |

| AWWA | DN50 to DN3600+ |

AWWA standards dominate large-diameter pipelines, while DIN is more common in small to medium utility systems.

4. Design Philosophy

DIN Valves

- Compact and lightweight

- Optimized for tight installations

- Cost-effective

- Popular in EPC and district cooling projects

AWWA Valves

- Heavier body sections

- Higher corrosion allowance

- Long-term durability focus

- Preferred for buried and critical water mains

5. Testing & Inspection

| Parameter | DIN | AWWA |

|---|---|---|

| Hydrostatic Testing | EN 12266 / EN 1074 | AWWA C500/C509/C515 |

| Leakage Criteria | Defined leakage limits | Zero or near-zero leakage |

| Service Focus | Utility & industrial | Water authority & municipal |

AWWA testing requirements are often more conservative, especially for seat leakage.

6. Coating & Corrosion Protection

Both standards typically require:

- Fusion Bonded Epoxy (FBE)

- Potable water-approved coatings

- Minimum DFT of 250–300 microns

However, AWWA often specifies stricter coating inspection and holiday testing, especially for buried pipelines.

7. Applications Comparison

| Application | Preferred Standard |

|---|---|

| Municipal water networks | DIN / AWWA |

| District cooling | DIN |

| Desalination plants | DIN |

| Large water transmission mains | AWWA |

| Fire water systems | AWWA |

| Industrial utility piping | DIN |

Which Standard Should You Choose?

Choose DIN when:

- Project is in Europe, Middle East, or Asia

- District cooling or utility pipelines are involved

- Space and weight optimization is required

- EN standards are specified by the consultant

Choose AWWA when:

- Large-diameter water pipelines are involved

- Buried or long-term municipal networks are required

- Water authority mandates AWWA compliance

- High safety margin and durability are critical

DIN vs AWWA – Cost Implications

- DIN valves are generally more economical and easier to source

- AWWA valves are typically heavier and more expensive, especially in large sizes

- Logistics and installation costs are often higher for AWWA due to weight

GCC Valves – DIN & AWWA Expertise

At GCC Valves, we supply both DIN and AWWA compliant valves tailored to project-specific requirements across the GCC.

We support:

- DIN / EN valves for district cooling, desalination, and utility projects

- AWWA valves for large municipal and fire water systems

We provide:

- EN 10204 3.1 Material Test Certificates

- Hydrostatic & seat leakage test reports

- Coating & holiday testing certificates

- Datasheets, GA drawings, and full QA/QC documentation

Our valves are supplied to projects aligned with SWCC, NWC, ARAMCO, ADNOC, SABIC, MARAFIQ, and BAPCO specifications.

Final Thoughts

DIN and AWWA are not competing standards, but different engineering philosophies designed for different applications. Selecting the correct standard early in a project avoids compatibility issues, reduces rework, and ensures long-term reliability.

For expert guidance on DIN vs AWWA valve selection, consult GCC Valves. | MiddleEastPiping.com