Flexible Coupling is engineered to connect two shafts, transmitting torque while accommodating angular, parallel, or axial misalignment between them. This coupling type is essential for reducing vibration, shock absorption, and compensating for minor misalignments, thereby extending the life of connected machinery. Widely used in pumps, compressors, motors, gearboxes, turbines, and industrial machinery, flexible couplings enhance operational reliability and efficiency in oil and gas, petrochemical, power generation, water treatment, and manufacturing sectors.

Manufactured from high-quality materials such as carbon steel, stainless steel, and alloy steel, flexible couplings are built to withstand harsh operating conditions, including high torque, variable loads, and temperature fluctuations. They are available in a variety of designs, such as elastomeric, gear, disc, and grid couplings, to meet the specific needs of different applications.

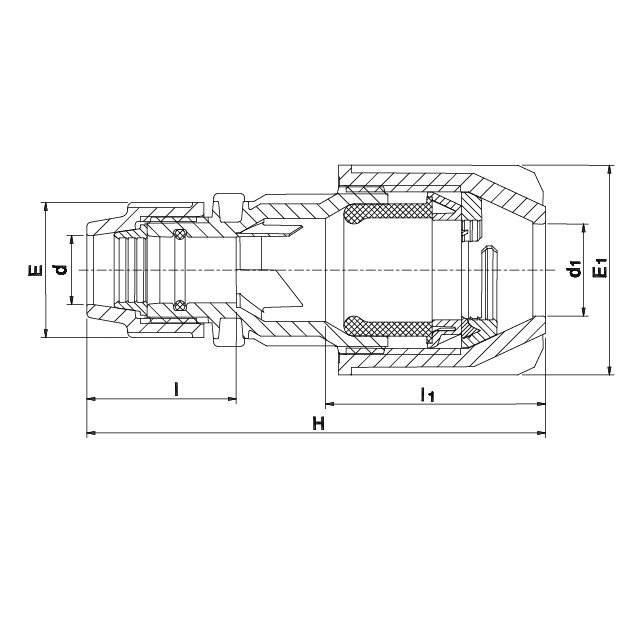

Specifications:

- Size Range: Custom sizes available to fit different shaft diameters

- Torque Capacity: Up to high-torque industrial specifications

- Material Options: Carbon Steel, Stainless Steel, Alloy Steel, Elastomers (for flexible elements)

- Design Standards:

- AGMA, API, or customer-specific standards

Manufacturers:

- Rexnord

- Lovejoy

- SVR

- Martin Sprocket & Gear

Applications:

- Pumps and Compressors

- Motors and Gearboxes

- Turbines and Industrial Rotating Machinery

- HVAC Systems

- Power Generation and Transmission

Advantages:

- Misalignment Compensation: Reduces stress on connected shafts, prolonging equipment life.

- Vibration Damping: Minimizes vibrations and noise for smoother operation.

- Shock Absorption: Protects machinery from sudden load changes.

- Versatile Material Options: Suitable for various operating conditions and environments.

For more information or to discuss your project needs, contact us today. Our Flexible Couplings provide high-performance, reliable solutions for a range of industrial applications.