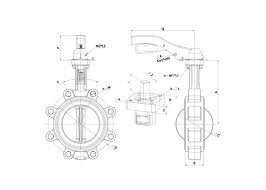

Concentric Butterfly Valve is the most common and basic design of butterfly valve, where the shaft/ stem passes through the exact centerline of the disc, and the disc itself sits in the center of the bore. The sealing element (usually elastomeric seat like EPDM, NBR, or PTFE) is lined inside the valve body, creating a soft seat sealing mechanism. A Concentric (Resilient Seated) Butterfly Valve is the go-to economical valve for low-pressure, general service where tight shut-off is required. For higher pressure or temperature, customers should be guided toward double offset (high-performance) or triple offset (metal seated) designs.

Key Design Features

-

Disc Position: Centered in the pipe bore.

-

Stem Position: Shaft runs through the center of the disc.

-

Sealing: Achieved by compression between the disc edge and the soft seat (rubber/liner).

-

Body Type: Commonly wafer type, lug type, or double-flanged.

-

Size Range: DN 40 to DN 2000+ (NPS 1 ½” to 80”).

-

Pressure Class: Typically up to PN16 / Class 150 (low to medium pressure applications).

Advantages

-

Lightweight and compact design compared to gate/globe valves.

-

Cost-effective solution for large-diameter flow control.

-

Easy installation and maintenance.

-

Quick operation (quarter-turn, 90°).

-

Tight shut-off (bubble-tight) when resilient seat is intact.

Limitations

-

Not suitable for high-pressure or high-temperature service (better to use Double Eccentric or Triple Offset Butterfly Valves in those cases).

-

Seat wear can occur with abrasive fluids.

-

Limited chemical compatibility depending on seat material (must select EPDM, NBR, or PTFE accordingly).

Typical Applications

-

Water treatment plants (raw water, cooling water, wastewater).

-

HVAC systems (chilled water, air handling).

-

Food & beverage / pharma (when fitted with sanitary seat materials).

-

General industrial services (low-pressure oil, gas, chemicals).

-

Marine applications (ballast systems, seawater pipelines).

Buy now Valves at GCCValves.com

And Pipes at MiddleEastPiping.com