Air release valves play a critical role in the safe and efficient operation of pressurized pipeline systems. Improper air management can lead to pressure losses, flow instability, corrosion, excessive energy consumption, and severe hydraulic failures such as water hammer or pipeline collapse.

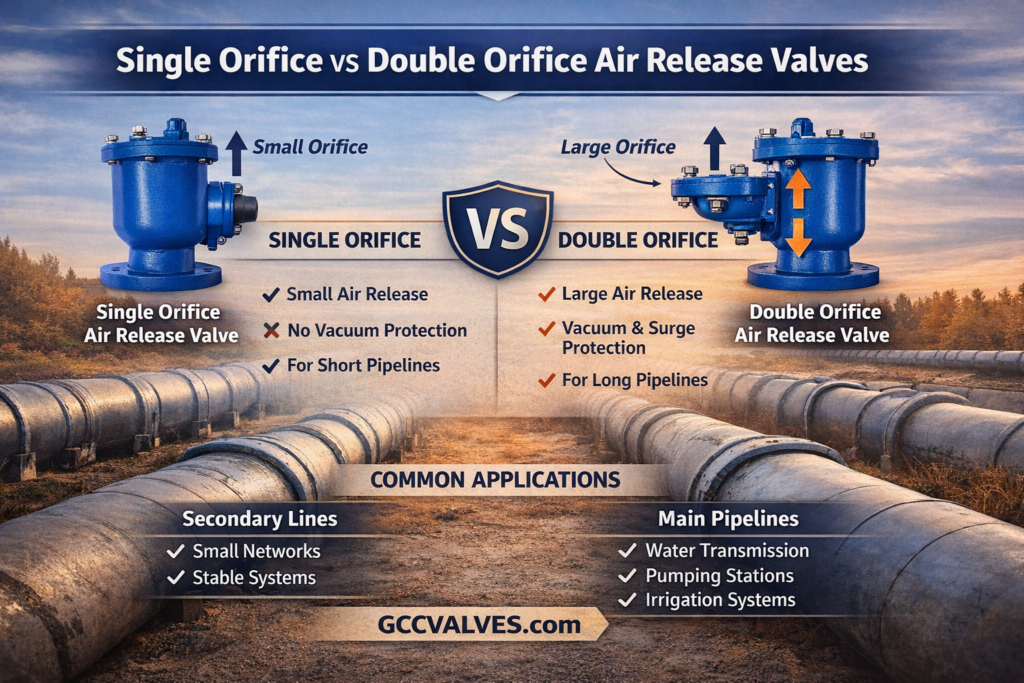

Among the most commonly specified types are Single Orifice Air Release Valves and Double Orifice Air Release Valves. While both serve the purpose of air management, their functionality, protection level, and application suitability differ significantly.

This blog provides a detailed comparison to help engineers and project teams select the correct valve type based on system requirements.

Why Air in Pipelines Is a Problem

Air enters pipelines during:

- Initial filling

- Draining and maintenance

- Pump start/stop cycles

- Leakage or negative pressure zones

Entrapped air can cause:

- Reduced flow capacity

- Increased head loss and energy consumption

- Erratic pressure fluctuations

- Corrosion and pipe damage

- Risk of vacuum collapse

Air release valves are therefore mandatory components in modern water, district cooling, and utility networks.

What Is a Single Orifice Air Release Valve?

A Single Orifice Air Release Valve is designed primarily to release small volumes of accumulated air from a pressurized pipeline during normal operation.

How It Works

- Continuously discharges trapped air pockets under pressure

- Uses a small orifice controlled by a float mechanism

- Operates only when the pipeline is pressurized

Key Characteristics

- Compact and simple design

- Releases air gradually during operation

- Does not provide effective vacuum protection

- Limited air intake during pipeline draining

Typical Applications

- Short pipeline runs

- Low-risk networks

- Systems with minimal elevation changes

- Secondary or branch pipelines

What Is a Double Orifice Air Release Valve?

A Double Orifice Air Release Valve combines two air-management functions in one valve body:

- Large orifice for high-volume air release and vacuum protection

- Small orifice for continuous air release during operation

How It Works

- Releases large volumes of air during pipeline filling

- Allows rapid air intake during draining to prevent vacuum

- Continuously discharges trapped air during normal service

Key Characteristics

- Dual-function design

- Protects against vacuum collapse

- Reduces water hammer risk

- Suitable for dynamic and long-distance pipelines

Typical Applications

- Water transmission mains

- Pump discharge lines

- District cooling networks

- Irrigation and raw water pipelines

- Long pipelines with elevation changes

Single vs Double Orifice – Technical Comparison

| Parameter | Single Orifice | Double Orifice |

|---|---|---|

| Air Release During Operation | ✔ Yes | ✔ Yes |

| Large Air Discharge During Filling | ✖ Limited | ✔ Yes |

| Vacuum Protection During Draining | ✖ No | ✔ Yes |

| Protection Against Pipe Collapse | ✖ No | ✔ Yes |

| Water Hammer Risk Reduction | Limited | High |

| Suitability for Long Pipelines | ✖ No | ✔ Yes |

| System Safety Level | Basic | High |

Design & Safety Implications

Single Orifice – Limitations

Single orifice valves do not provide sufficient protection during:

- Rapid filling

- Sudden pump shutdown

- Pipeline draining

Using only single orifice valves in critical pipelines may result in:

- Vacuum formation

- Pipe deformation or collapse

- Severe hydraulic shocks

Double Orifice – System Protection

Double orifice valves are considered system-protection valves, not just air release devices. They:

- Safeguard pipelines during transient events

- Improve hydraulic stability

- Extend pipeline service life

- Reduce maintenance and repair costs

For this reason, most GCC utilities and EPC consultants specify double orifice valves as standard for main pipelines.

Which One Should You Choose?

Choose Single Orifice When:

- Pipeline length is short

- System pressure is stable

- Risk of vacuum is minimal

- Used as a supplementary air release device

Choose Double Orifice When:

- Pipeline length is long

- Elevation changes exist

- Pumping systems are involved

- High flow velocities are present

- System safety and longevity are critical

In most modern infrastructure projects, Double Orifice valves are the preferred and safer choice.

Common Specification Practice in KSA & UAE

Across KSA, UAE, and GCC utility projects, the general practice is:

- Double Orifice Air Release Valves on main pipelines and pump discharge lines

- Single Orifice Air Release Valves on secondary lines or as supplementary protection

Authorities and consultants increasingly mandate dual-function air valves to reduce lifecycle risk and improve operational reliability.

GCC Valves – Air Release Valve Expertise

GCC Valves supplies both Single Orifice and Double Orifice Air Release Valves compliant with international standards and tailored to GCC operating conditions.

Our valves are widely used in:

- Water transmission networks

- District cooling systems

- Desalination plants

- Irrigation and utility pipelines

We support projects across KSA, UAE, and the GCC with:

- Technical selection assistance

- Datasheets and GA drawings

- Testing and QA/QC documentation

- Project-specific compliance

Final Conclusion

The choice between Single Orifice and Double Orifice Air Release Valves is not merely a cost decision—it is a system safety decision.

- Single Orifice valves manage trapped air

- Double Orifice valves protect the entire pipeline

For critical infrastructure, long pipelines, and pumping systems, Double Orifice Air Release Valves are strongly recommended to ensure long-term reliability, safety, and performance. For other piping accessories click here