Ductile Iron Check Valve are designed to allow flow in one direction and prevent reverse flow. They protect pumps, compressors, and pipelines from backflow damage, water hammer, and pressure surges. Available in swing, wafer, or dual-plate configurations, these valves are widely used in water distribution, wastewater, desalination, firefighting, and industrial utility networks. Ductile Iron Check Valve for SWCC & NWC.

Specifications:

-

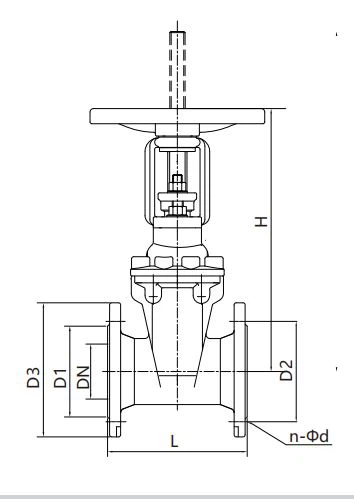

Nominal Diameter: DN50 to DN1200 (2” to 48”)

-

Nominal Pressure:

-

Class 125 / 150

-

PN10, PN16, PN25

-

150 PSI / 200 PSI / 250 PSI

-

-

End Connection: Flanged (ASME B16.1 / B16.42, EN 1092-2), Wafer Type (ISO 7005), Mechanical Joint (AWWA C508)

-

Types Available:

-

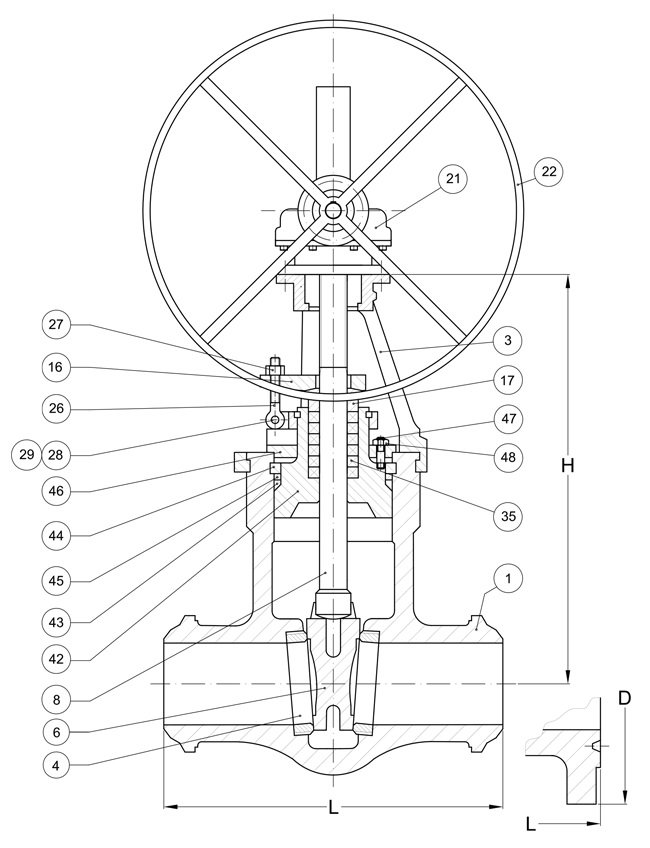

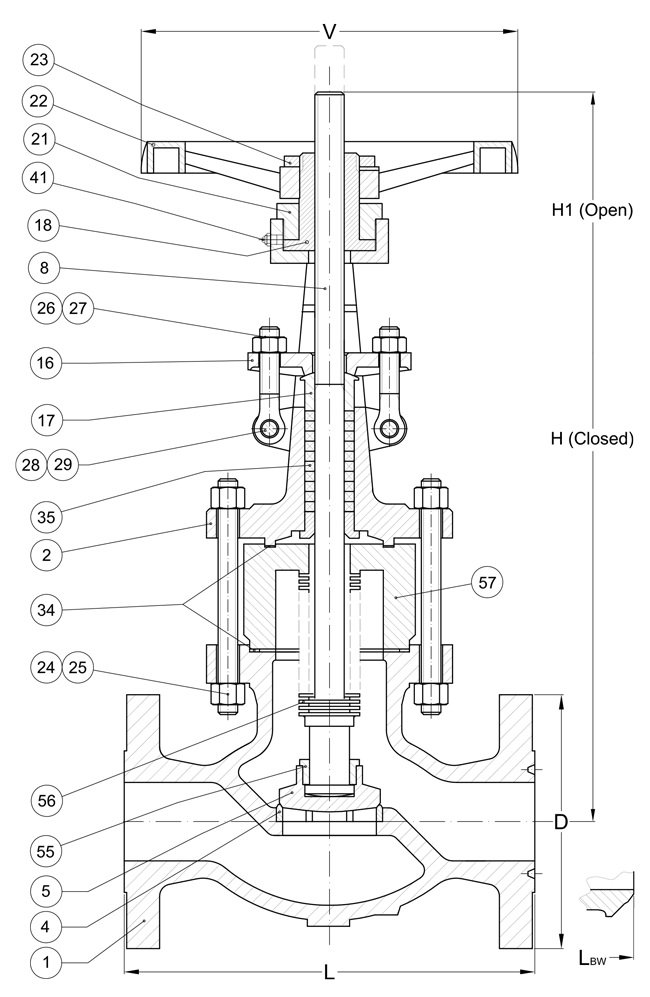

Swing Check Valve (with flanged ends, suitable for large pipelines)

-

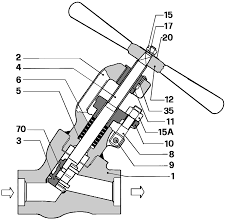

Wafer Check Valve (compact, space-saving design)

-

Dual Plate Check Valve (high performance, lightweight)

-

Design Standards:

-

AWWA C508 (Swing Check Valves)

-

EN 1074-3 (Check Valves)

-

API 598 (Valve Testing)

-

ISO 9001 (Quality Management System)

Manufacturers:

-

SVR Ductile Iron Check Valve

-

AVK Swing & Wafer Check Valves

-

TALIS Check Valve

-

KSB Check Valve

-

Additional sourcing available from China, India, Europe, and USA

Applications

Ductile Iron Check Valves are essential in:

-

Municipal Water Supply & Distribution

-

NWC / SWCC Projects

-

Wastewater & Sewage Treatment

-

Desalination Plants

-

Firefighting Networks

-

Industrial Utility & Cooling Water Systems

With available ratings of Class 125/150, PN10–PN25, and 150–250 PSI, these valves ensure reliable backflow prevention, extended service life, and compliance with international standards.

At GCC Valves, we provide check valves with full QA/QC documentation, including MTCs, ITPs, and inspection records, meeting project requirements for Aramco, ADNOC, SWCC, NWC, SABIC, and BAPCO.